Services

From the first screw to the last pressure test: We take care of the complete installation, servicing and commissioning of your hydraulic systems and

lubrication systems – reliably, efficiently and in compliance with standards. Our experts ensure smooth implementation on site – including system testing, documentation

and instruction.

24

h

HYDRAULIC SERVICES

Services

From the first screw to the last pressure test: We take care of the complete installation, servicing and commissioning of your hydraulic systems and

lubrication systems – reliably, efficiently and in compliance with standards. Our experts ensure smooth implementation on site – including system testing, documentation

and instruction.

Our range of services

INSTALLATION, SERVICE AND COMMISSIONING OF HYDRAULIC SYSTEMS & LUBRICATION SYSTEMS

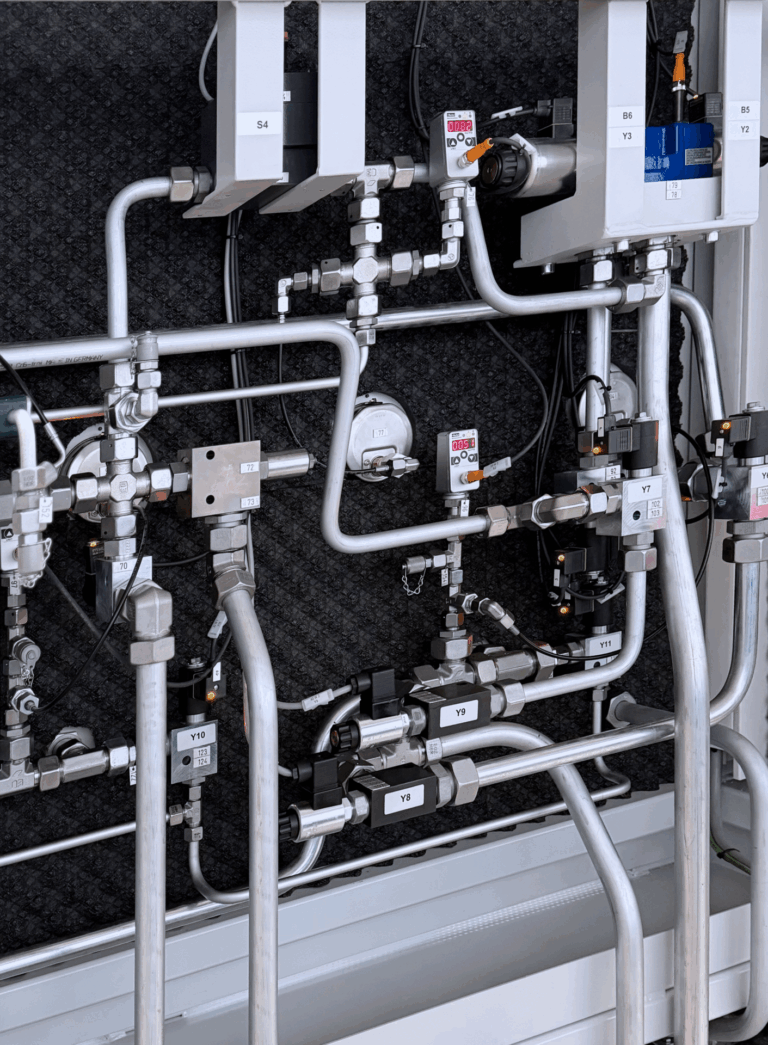

From the first screw to the last pressure test: The PHILIPPGRUPPE takes care of the complete installation, servicing and commissioning of your hydraulic systems and lubrication systems – reliably, efficiently and in accordance with standards. Our experts ensure smooth implementation on site – including system testing, documentation and instruction. Your benefits: everything from a single source, short project lead times, professional implementation – for safe and long-lasting operation of your systems.

WELDING TECHNOLOGY

In welding technology, we combine expertise with quality – for permanently resilient connections to the highest standards. We offer welding solutions for pipelines, system components and special constructions – including test certificates and traceability. Your benefits: maximum production reliability, certified quality and customized solutions – from a single source. Put your trust in welding technology that delivers what it promises.

HYDRAULIC PIPING

Whether complex systems or individual special solutions: The PHILIPPGRUPPE offers you precisely manufactured hydraulic piping to meet the highest requirements. From planning and pipe processing to installation With state-of-the-art technology, trained specialists and decades of experience, we realize piping and connection systems in steel or stainless steel – precisely tailored to your system.

Your benefits: short response times, high level of vertical integration, ready-to-install delivery – including pressure testing and documentation on request. Fast. Safe. PHILIPP.

RE-TUBING

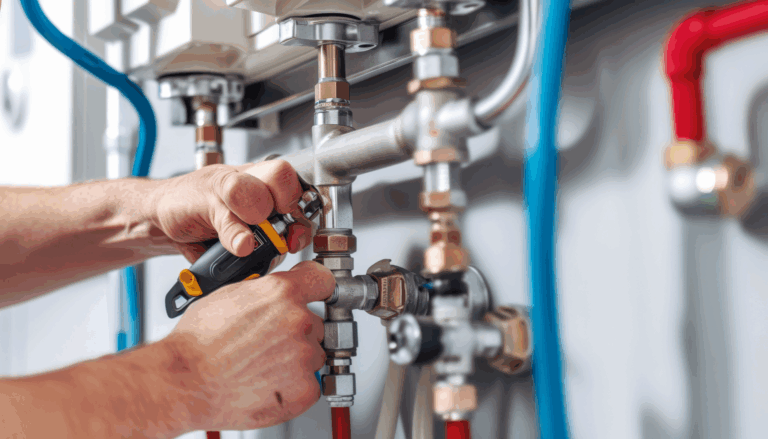

Hydraulic hoses are subject to natural wear and tear – timely re-hosing protects against breakdowns, leaks and safety risks. The PHILIPPGRUPPE offers you fast, professional and standard-compliant renewal of your hose lines – on site or in our workshop.

We take care of disassembly, assembly and installation, including marking, pressure testing and documentation. Whether individual replacement or complete system – we get your hydraulics back in top form.

PIPE INSTALLATION

Precision, safety and compliance with standards are what count when it comes to pipe installation. The PHILIPP GROUP guarantees you certified quality in accordance with DIN EN ISO 9001, CE conformity and clearly documented manufacturer certificates.

Our assembly solutions meet all legal requirements and industry-specific standards – for maximum legal certainty and sustainable quality. Thanks to our seamless traceability of all components, we reliably support you in the documentation and quality assurance of your systems. Place your trust in tested processes and decades of experience – made by PHILIPP.

ON-SITE SERVICE

When every minute counts, our mobile on-site service is there for you: we come directly to your system – whether for fault analysis, re-tubing, pipe installation or maintenance. With fully equipped service vehicles, experienced technicians and short response times, we ensure minimum downtime and maximum operational reliability. Whether individual components or entire systems – we act in a solution-oriented and standard-compliant manner. Your benefits: no dismantling, no transportation, no loss of time. Simply call us – PHILIPP is there!

OFF-LINE FILTRATION

Contaminated hydraulic oil is one of the main causes of system failures. Our off-line filtration ensures permanently clean oil – regardless of ongoing operation. This increases the service life of your components and reduces maintenance costs. The PHILIPPGRUPPE offers you mobile or permanently installed solutions – including advice, installation and commissioning. Even the finest particles and water are reliably removed. Your benefits: continuous oil maintenance during operation, simple retrofitting, long-term protection of your hydraulic system. For more efficiency.

MAINTENANCE OF HYDRAULIC CYLINDERS

Hydraulic cylinders are central to the performance of your system – their regular maintenance and servicing protects against expensive breakdowns and extends their service life. The PHILIPPGRUPPE takes care of dismantling, cleaning, testing, repair and recommissioning for you – independently of the manufacturer and with a high level of expertise. Your benefits: short downtimes, precisely fitting spare parts, documented quality – with on-site service on request. You can rely on professional cylinder maintenance.

BENDING, FLANGING AND FORMING

Whether one-off production or series production: the PHILIPPGRUPPE offers professional bending, flanging and forming of pipes – precise, repeatable and in accordance with current standards. Using the latest technology, we manufacture customized solutions made of steel or stainless steel – for hydraulics, pneumatics and industrial applications. We also implement complex geometries economically and in accordance with standards.

Your benefits: high dimensional accuracy, perfect fit, minimal reworking – for fast installation and reliable function. Technology that fits.

STORAGE TESTS WITH TÜV

According to BetrSichV, pressure equipment must be tested regularly – this can be done safely, efficiently and sustainably with the innovative ID-E test method. The patented procedure developed by TÜV Thüringen uses the non-destructive EMAT ultrasonic principle and is particularly suitable for hydropneumatic bladder accumulators, nitrogen cylinders and hydraulic accumulators.

Your benefits: no disassembly, no transportation, no media or surface preparation required – with minimal interruption to operations. ID-E saves costs, conserves resources and tests up to 15 devices per day. Can be used throughout Germany, including free demonstrations by our specialists!

FLUID MANAGEMENT

Contaminated oil is often the cause of malfunctions and breakdowns in hydraulic systems. To prevent this, the PHILIPP GROUP offers the new Fluid On-Site Service, which reduces the time and effort required for oil analyses to a minimum.

With our high-quality particle counter, we reliably check the oil quality – determine the purity class and water content – and thus enable targeted, effective maintenance of your hydraulic system.

PREVENTIVE HYDRAULIC MAINTENANCE 4.0

Preventive maintenance and servicing pursues important goals: It reduces wear and tear and thus increases the service life of your systems, ensures their long-term existence and reduces maintenance costs by up to 70%. At the same time, unplanned downtime is avoided and workplace safety is significantly increased. With targeted prevention, the PHILIPP GROUP ensures that your systems remain efficient, safe and economical in operation.

HOSE FLASH SERVICE

Our Schlauchblitz service is available for you 24 hours a day, 365 days a year in the Aschaffenburg and Neuss regions. Thanks to an excellently stocked hydraulic workshop directly on board, our technicians have all common spare parts with them. We can get your broken-down and broken-down machines up and running again as quickly and easily as possible!

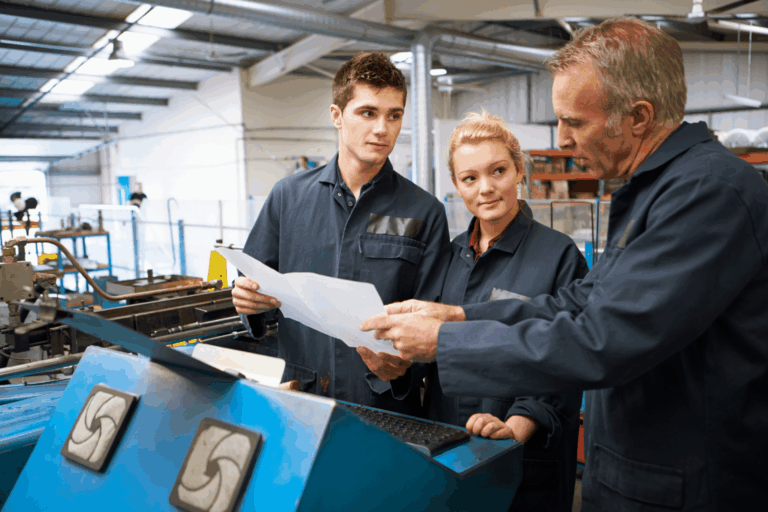

TRAININGS

Our seminars offer practice-oriented knowledge of hydraulic systems and components. We keep you up to date – from the basics of hydraulics and fault analysis to hose and fitting technology. Qualification as a competent person for hydraulic hose lines and topics relating to occupational safety are also part of our offer.

LET'S WORK TOGETHER

Contact our hydraulic service team

OUR PARTNERS IN THE HYDRAULICS INDUSTRY