UVV inspection and repair service

The UVV test is an important part of occupational health and safety, ensuring that work equipment and devices meet the requirements of accident prevention regulations. The PHILIPPGRUPPE offers a comprehensive range of UVV tests, which are carried out by knowledgeable experts.

INQUIRY

TEST SERVICE

UVV inspection and repair service

The UVV test is an important part of occupational health and safety, ensuring that work equipment and devices meet the requirements of accident prevention regulations. The PHILIPPGRUPPE offers a comprehensive range of UVV tests, which are carried out by knowledgeable experts.

Why does it need to be checked?

1. legal requirements

BetrSichV, UVV and standards regulate the scope of testing and corresponding test cycles. We support you in complying with the laws and guidelines. So you are always on the safe side.

2. occupational safety

Work equipment that is regularly and expertly inspected and complies with legal requirements ensures a safe workplace.

3. cost reduction

By using tested work equipment, you reduce the risk of downtime and the resulting consequential costs.

What do we check?

We test for you in accordance with the applicable DGUV:

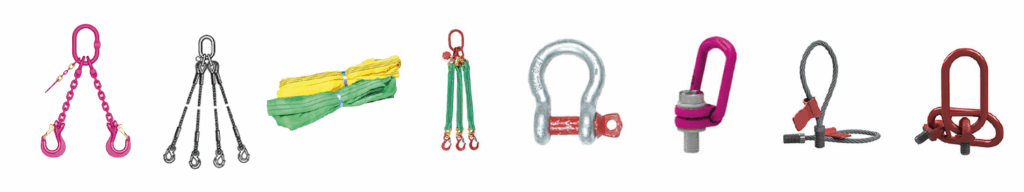

LOAD HANDLING ATTACHMENTS & SLINGS

ACCORDING TO DGUV-RULE 109-017

Load beams, grabs, clamps, drum handling, turning beams, crane forks, coil hooks, special hooks, Wirbelstar magnetic lifters, Lifty, lifters, rope loops, vacuum lifting technology, rope clamps

ACCORDING TO DGUV-RULE 101-001

Sling chains, sling ropes, textile slings, S-hooks, shackles, round sling hangers, attachment points

GANTERUD - LOAD BALANCING

ACCORDING TO MANUFACTURER SPECIFICATIONS + APPLICABLE STANDARDS

INDUSTRIAL TRUCKS

ACCORDING TO DGUV REGULATION 68

Pallet truck

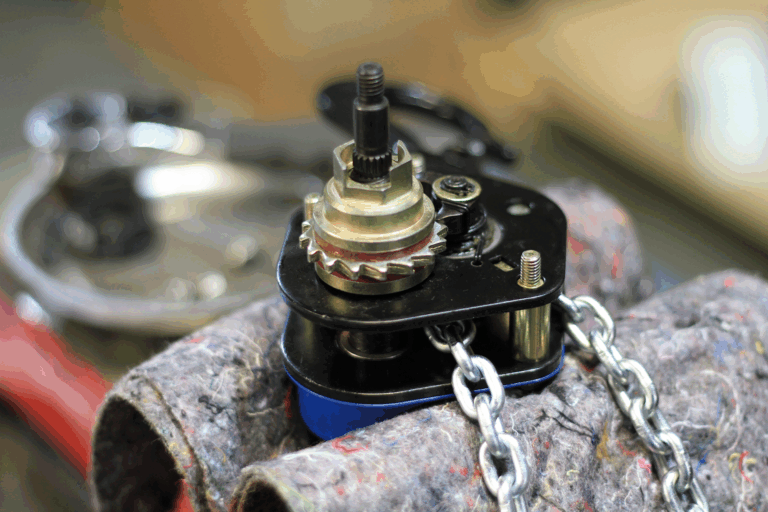

WINCHES, LIFTING AND PULLING DEVICES

ACCORDING TO DGUV-RULE V54

Ratchet hoists, spur gear chain hoists, cable hoists, cable winches, trolleys, grab hoists, rack and pinion winches, lifting devices, machine jacks

LADDERS AND STEPS

ACCORDING TO DGUV-INFORMATION 208-016

Ladders, steps, platform stairs, bridging steps, access technology, shaft ladders

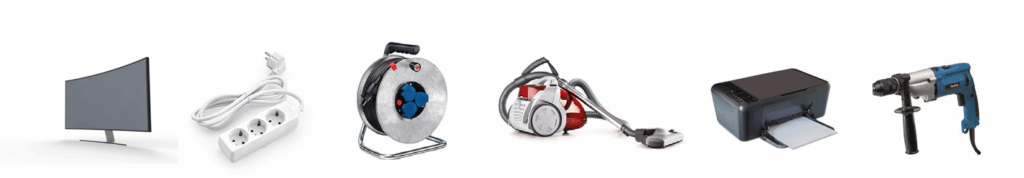

ELECTRICAL SYSTEM AND EQUIPMENT TESTING

ACCORDING TO DGUV REGULATION 3

Electrical system and equipment testing Portable electrical appliances, e.g. drills, angle grinders, vacuum cleaners, extensions, monitors and printers

DOORS AND GATES

ACCORDING TO DGUV INFORMATION

208-022

(AND 208-044, AND DGUV PRINCIPLE 308-006)

Roller shutters, rolling grilles, sliding doors, sectional doors

LIFT TABLES

ACCORDING TO DGUV PRINCIPLE 308-002

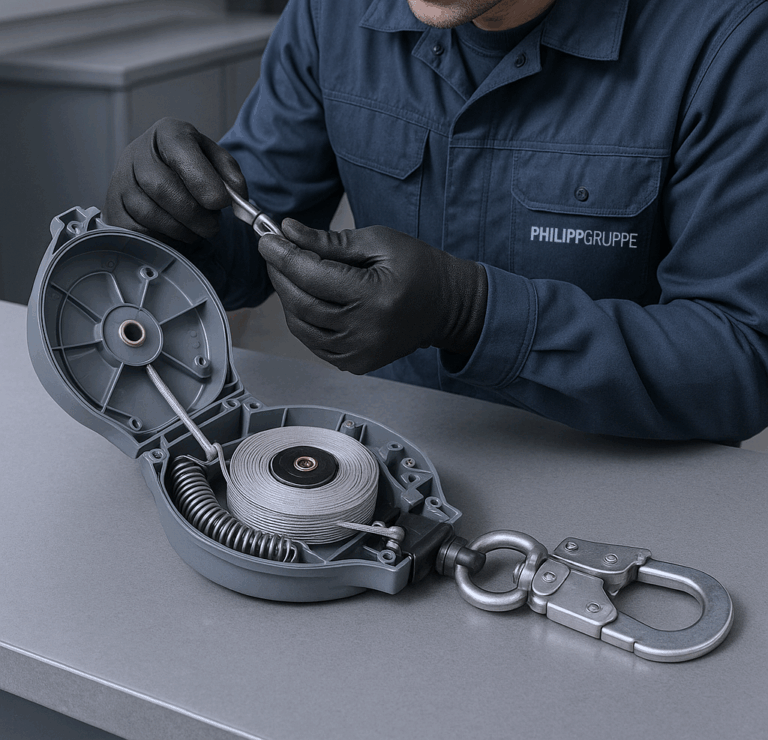

PERSONAL PROTECTIVE EQUIPMENT AGAINST FALLS FROM A HEIGHT

ACCORDING TO DGUV-RULE 312-906

Safety harnesses, lanyards, fall arresters (HSG), rescue lifting devices, abseiling devices, permanent fall protection systems

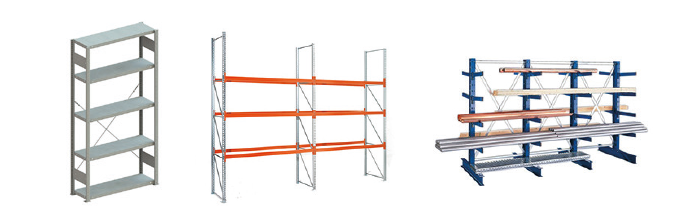

REGALE

ACCORDING TO DGUV-RULE 108-007 + DGUV INFORMATION 208-043

Shelving racks, pallet racks, cantilever racks, drive-in racks, drive-through racks

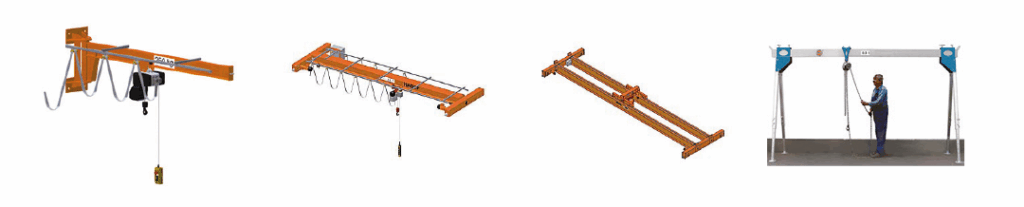

CRANE SYSTEMS

ACCORDING TO DGUV REGULATION 52 + 53

Pillar jib cranes, wall-mounted jib cranes, overhead monorail systems, bridge cranes, workshop cranes, overhead traveling cranes, electric chain hoists, electric wire rope hoists

How do we check?

Visual and dimensional inspection

BetrSichV, UVV and standards regulate the scope of testing and corresponding test cycles. We support you in complying with the laws and guidelines. So you are always on the safe side.

Magnetic crack detection

Using a magnetic field with fluorescent liquid and UV lighting, the smallest cracks are made visible and reliably detected by our test technicians.

Function test

Professional inspection of the prescribed lifting function, the functionality of all parts, the effectiveness of the safety devices and the brake test with load in the nominal load range.

Load test

The load test is carried out in accordance with the legally prescribed test loads.

Revisions

We are service partners for abseiling devices and fall arresters from renowned manufacturers.

Your advantages

Always on the safe side

Have your work equipment checked regularly. In this way, you are not taking any unnecessary risks and can extend the service life of your work equipment at the same time. The PHILIPP inspection and repair service team has experience with a wide variety of work equipment and will be happy to remind you in good time of your regular inspection appointment. For long-term orders, we are also happy to offer you individual solutions tailored to your needs.

On-site inspection

You have no logistical effort and benefit from minimal downtime. The spare parts we carry enable us to rectify the majority of faults immediately. In the case of major repairs, you will receive a cost estimate as well as rapid repair and return of your work equipment.

Manufacturer-independent tests

We test for you in an uncomplicated manner and for all common makes.

Always available

Simply arrange a test appointment with us. We will be happy to provide you with a customized offer.

Modern data management

All products and their test history can be viewed anywhere by our test and repair service team.

Expert information

Damage can be avoided by using your work equipment correctly. We will of course provide you with all the necessary information on correct use and damage prevention.

OUR PARTNERS IN ROPE AND LIFTING TECHNOLOGY